menu

close

Mieko Fujimori, known as "Mrs." Fujimori, is responsible for the dyeing process of indigo-dyed washi.

She married into the Fujimori family, which runs Awagami Factory, and has been supporting the paper-making process from behind the scenes.

She began working on indigo-dyed washi in earnest after, she had finished raising her children.

While helping her mother-in-law, Tsune, she learned various techniques for dyeing washi with indigo.

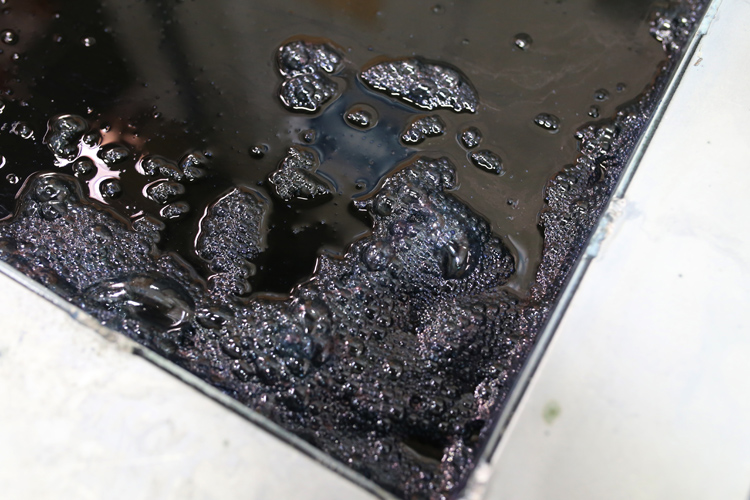

Indigo flowers※1 are blooming, so the indigo is in good condition today," she says, pointing to the indigo jar(Ai Game).

Indigo is made by fermenting (tateru) sukumo to produce a dye solution.

“Sukumo" cannot be dyed unless the indigo leaves are fermented and reduced with alkali to the so-called "tateta" state.

It is also important to determine the oxidation-reduction state of the dye solution in the indigo jar to ensure that the dye is dyed exactly as imagined.

※1 indigo flowers : The froth which appears on the surface of the fermented indigo-dyed solution.

On this day, plain dyed "navy blue paper" is dyed from the morning.

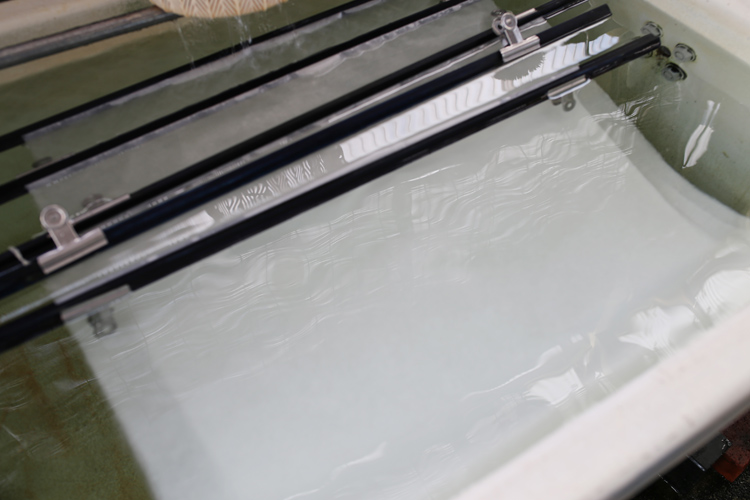

Washi, coated on both sides with konjac glue to make it water-resistant, is soaked in water

thoroughly before dyeing.

In this way, it can be penetrated into the paper evenly.

The paper is hung from a sling and slowly raised and lowered by a rope while the paper is dipped

into an indigo bottle for dyeing.

Once the paper is completely immersed in the dye solution, measure the soaking time with a timer.

After a few minutes, the rope is slowly pulled up to reveal brown-dyed paper.

Oxidation occurs when the paper is exposed to air thoroughly, turning it green.

In order to fully remove the scum remaining on the paper, the paper is thoroughly rinsed in the shower, and the scum is washed away to reveal the blue color.

After repeating this process several times, the paper is finally dyed a deep indigo color.

Finally, she dips it in water to remove the scum completely and hangs it to dry naturally.

She will do "Bokashi Dyeing " in the afternoon.

Bokashi Dyeing is a dyeing method with an appealing natural gradation from dark to light to white.

In order to create an even and smooth gradation, she has to move her hands all the way down therope slowly and deliberately. If she stops anywhere, a linear pattern will form, so she carefully and slowly drags the rope.

The paper is then soaked in water, dehydrated, and spread out on a table to dry naturally in order to preserve the beautiful wrinkles. The indigo-dyed washi paper made in this way was made into lanterns and sold at The Conran Shop. I am happy that my paper has been transformed into an attractive product with a new sensibility," she says with a smile on her face.

On this day, only 10 sheets of paper were dyed by the evening.

The number of sheets that can be dyed in a day is thus negligible.

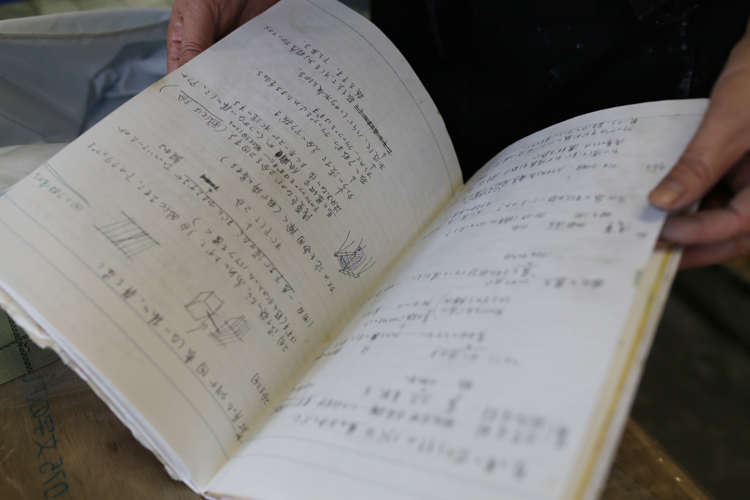

During the final soaking, she wrote a record of the day's work in a notebook.

When we asked her to show us the notebook, which she has been keeping since she started her

indigo dyeing business, she wrote down a meticulous record of her work.

She said “By recording their experiences in this way, they are able to make decisions when trying something new.”

She says with a twinkle in her eye, "In order to produce the indigo color I envision, I am willing to take on any challenge, no matter how hard it may be.

We accept custom orders and large-lot production.

Please feel free to contact us.